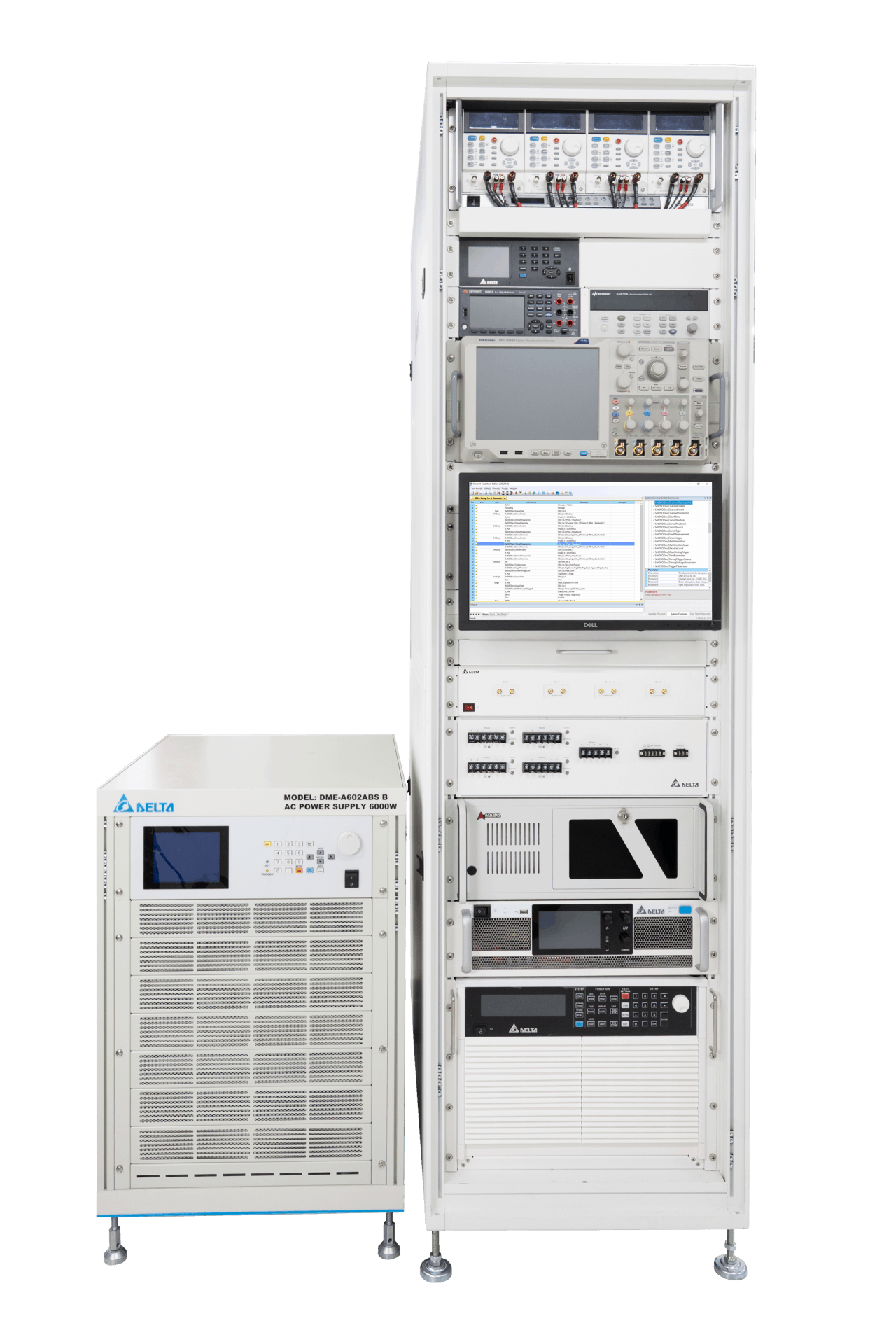

As a leading manufacturer of power supplies, Delta has utilized decades of R&D and manufacturing experience on power supplies to develop a highly efficient power supply automated testing system. The system has in-built power testing items that meet international standards, and it allows testing procedures to be edited easily using software, giving users automated testing capacity that can substantially accelerate the product verification process.

R&D and manufacturing of power supplies require complex test procedures to ensure stable performance and quality. In the past, testing was mainly conducted manually, with data obtained through traditional statistical methods. This approach is not only time-consuming, but it also makes it difficult to obtain precise data. This is further complicated by different power supplies having different power rating, which requires additional testing equipment to be purchased.

Delta’s Power Supply Automatic Test System utilizes the Delta Smart 1 ATS platform as its core, integrating hardware equipment and editing of test items and programs Its open framework and powerful integration ability provide flexibility for the expansion of hardware equipment and testing items, allowing it to be used to test various power supplies.

Delta’s Power Supply Automatic Test System offers a simple, flexible, and precise testing method for the R&D, testing, and manufacturing of various power supplies, ensuring high quality and performance of products.

Product characteristics:

- Modular software and hardware design for establishing systems based on different needs

- Expandable high-power electric load that can meet the demands of various power tests

- In-built function testing items in line with international standards

- Intuitive software user interface that does not require coding

- Supports customizable test reports

- Multiple objects can be tested at once for shorter testing times