Anticipating Industry Challenges, Achieving a Successful Equation for Efficiency, Risk Management, and Long-Term Operation

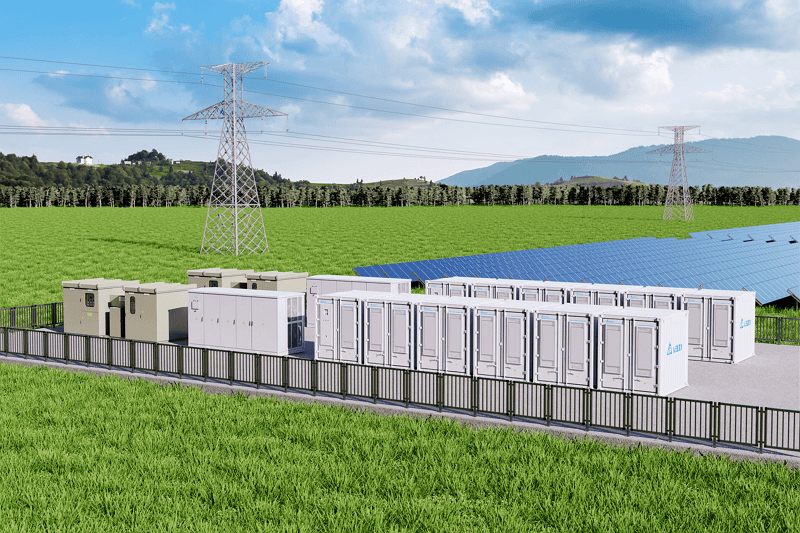

Delta, a global leader in power and energy management, presents the next-generation containerized battery system (LFP battery container) that is tailored for MW-level solar-plus-storage, ancillary services, and microgrid projects. Addressing challenges such as rising construction costs, land scarcity, and security, this battery system from Delta emphasizes balance among construction efficiency, risk management, and long-term success. The new battery container, housed in a standard 10ft container, streamlines installation with its positioning tolerance space and closed-cabinet wiring design to shorten installation timelines. Safety features include the adopting of LFP cells, comprehensive monitoring of each cell, redundant sensors, fire-resistant materials, and built-in sprinkler system. These collectively mitigate thermal runaway risk to deliver robust asset protection by ensuring swift responsiveness to potential fire hazards and effective prevention of heat propagation. Configurations range from 708 kWh to 7.78 MWh, with global order-taking start from Q2, 2024.

Jim Chen, Vice General Manager of Delta’s Energy System Solutions Business Division, emphasized, “As the scale of energy storage projects grows and the applications diversify, owner expectations regarding installation efficiency and system completeness will continue to rise. Delta’s goal is to develop a battery system that considers a comprehensive range of relevant factors, including a balance between cost and safety. Delta is equipped to address all challenges from planning to operation, thus protecting our client’s ROI while also preventing damage to the environment as well as other interests of greater society. The battery container not only reflects Delta’s accumulated experience in the energy storage field but also underscores our commitment to contributing to the steady development of industry.”

Key Features of the Delta Containerized LFP Battery Container:

- Optimal Land Utilization: Flexible capacity configurations ranging from 708 kWh to 7.78 MWh, integrated with site controllers, UPS, and other system components. Eliminates the need for additional cabinets and conserves ground space.

- Efficient On-Site Operations: Full-container transportation without removing the battery modules. Flexible dust connectors between containers with tolerance space for positioning prevent redundant lifting. Lateral cable entry design dispenses with the need for underground trenching, enhancing installation and cabling efficiency. On-site installation can be completed without opening the cabinet, thus preventing moisture and dust from entering.

- Asset Security Assurance: Core risk management principles include the use of lithium iron phosphate (LFP) cells for higher safety and a longer lifespan. Comprehensive monitoring of each cell and active protection mechanisms are designed into the system, reducing the risk of initial thermal runaway. Multiple environmental monitoring and protection functions are installed to respond promptly to potential fires. Built-in fire-resistant materials and optional sprinkler systems are also in place to prevent heat propagation and control damage in the event of a disaster.

- Long-Term Stable Operation: Pro-Active cell balancing technology enhances battery stability by performing dynamic cell balancing while charging and discharging to increase system discharge capacity. The Battery Management System (BMS) ensures a quick communication response and real-time data exchange, safeguarding the system’s operational safety. Redundant communication and control ensure the system remains controllable and achieves set performance at all times.

The Delta’s LFP battery container has completed UL 9540A testing and obtained UL 1973, IEC 62619 (including thermal runaway), UN38.3, and IEC 60730 certifications. For further information on the Delta LFP Battery Container, please contact Delta or visit our website.

More Information: